- MegaTec shall work with any client as a partner.

- Design only, designs review only, executions only "as a contractor"

- installation supervision only and turnkey projects all are available as per our client's convenience.

- Chronic problem total solution is also available with warranty.

- MegaTec can help you to get the required international license and/or certificate (such as GMP certificate and FDA license) due to proper performance of HVAC system (pharmaceutical).

- Also MegaTec have the capability to analyze and solve any HVAC noise related problem due to any HVAC equipment air born noise, as per ASHRAE procedure.

- Comprehensive smoke management system, as per ASHRAE and BS requirements, shall be designed only, executed only and turn-key system whenever required.

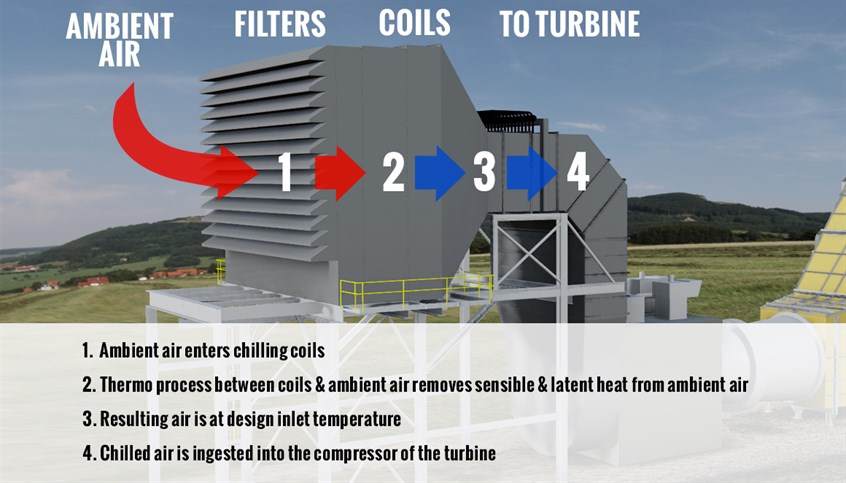

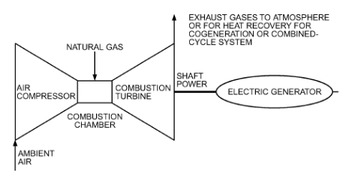

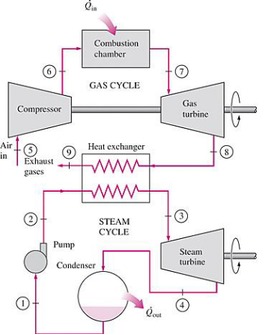

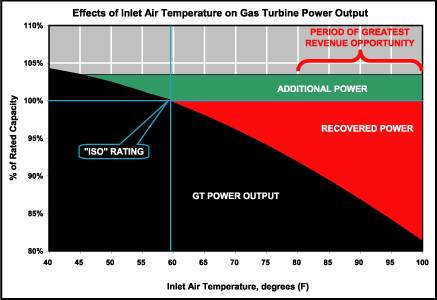

MegaTec can recover the total wasted electrical power from any gas turbine power station due to higher ambient temperature than ISO condition. The recovered power in Egypt shall be 10% : 15% of the station nominal output power (the higher the ambient the higher the recovered power). The gas turbine power stations in Egypt represent 52.4% of the total power stations, as per EEHC 2016 report (SC=7,845 MW, CC = 12,527 MW, GT = 20,372 MW & Total =38,857 MW). We customize the most economical solution for your power station based on our client financial capability and available technologies (Media Type Evaporative Cooler, Fog System, Chillers System, etc).

| Advantages (المميزات) | Dis-advantages (العيوب) |

|---|---|

| Capacity Enhancement when most needed & most valuable (i.e. reduce capital cost , reduce electricity selling rate & increase revenue) – (زيادة القدرة الكهربائية الخارجة من محطة التوليد عند الحاجة القصوى لها وكذلك عندما يكون ذلك أغلى مبيعاً للمستهلكين). | Additional investment fund. |

| Increased seller electrical power revenue, conserve fuel resources & increased fuel efficiency (زيادة إيرادات مبيعات الكهرباء للمستهلكين , وتقليل تكلفة إستهلاك الوقود , وتقليل معدل إستخدام الوقود لنفس القدرة المطلوبة). | Permanent power loss due to insertion ▲P. |

| Pay-back within 7 years max. & Gas Turbine Life Extension (إسترداد النقود فى غضون 7 سنوات بحد أقصى , وزيادة العمر الإفتراضى للتوربين الغازى). | Increased Combined-Cycle (CC) Efficiency as well for simple cycle (SC). (زيادة كفاءة الدورة البسيطة وكذلك كفاءة الدورة المركبة أيضاً). |

| Additional maintenance cost. | |

| Reduced grid-wide emissions (SOx, NOx , particulates, CO2, particulates and hydrocarbons). | Additional space. |

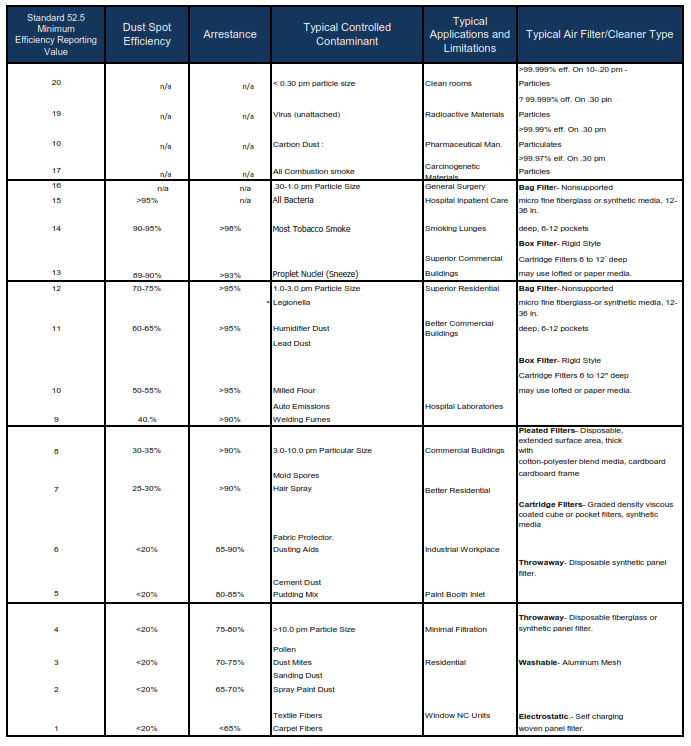

Pharmaceutical HVAC Systems

MegaTec shall be your partner to newly install your pharmaceutical factory HVAC system as per international standard, resolve the chronic problems in any existing HVAC system and help you to get the required international certificate and/or license. Cleanrooms can be used in electronic manufacturing, Pharmaceutical, Automotive and Research Facilities.

The formal US Federal standard 209 (FS209) had been withdrawn in November 2001.

The cleanest cleanroom is ISO Class 1 and the dirtiest cleanroom is ISO Class 9.

The qualification plan (QP) shall include all of the following

- 1. Functional requirement specifications (FRS).

- 2. Critical parameters and acceptance criteria.

- 3. Installation qualification (IQ).

- 4. Operational qualification (OQ).

- 5. Performance qualification (PQ).

- 6. Standard Operating Procedures (SOPs).

- 7. Preventive maintenance (PM), and.

- 8. Operator and maintenance personnel training.

| Typical pressurization control techniques for Clean Rooms | |||

|---|---|---|---|

| Comparison Factor | DP control | DF control | Hybrid (cascaded) control |

| How it deal with the differential pressure | It uses a pressure differential sensor to measure the pressure difference between a controlled room and an adjacent space (e.g., a corridor). | It assumes an offset value based on intuitive guesswork; this value is then used as a volumetric or mass flow difference between entering and leaving airflows through their airflow control devices. | It combines the pressure accuracy of DP and the stability of DF. The offset value (offset cfm) is resettable based on the pressure differential reading. The offset value reset schedule is predetermined, and the controller’s parameters are fixed manually in field (i.e. in this method the initial offset value (offset cfm) is fixed manually on site for each room). |

| Suitability | DP control is suitable for a tightly constructed room with limited traffic. | This method is suitable for open-style rooms or rooms with frequent traffic. DF normally maintains the same offset value throughout operation to keep pressurization constant. A constant-percentage offset value (i.e. offset cfm percentage) is sometimes used, but this creates a weaker pressurization at a lower flow. | This method is suitable for applications which require a very precise air flow direction control (which represents the most important factor in contamination control). |

| A constant-percentage offset value (i.e. offset cfm percentage) is sometimes used, but this creates a weaker pressurization at a lower flow. | |||

| How it deal with the offset air flow rate | It basically ignores the specific offset value (i.e. offset cfm) as required; instead, it directly controls the airflow control devices to achieve the required pressure differential between the controlled room and an adjacent space. | It controls the required offset air flow rate only regardless of the differential pressure readings between rooms. | It controls the required offset air flow rate and the differential pressure readings between rooms at the same time. |

| Additional required features | A door switch is recommended to trigger a reduced pressure-differential set point if the door opens. | Control circuit shall control the offset cfm only. | Control circuit shall control the offset cfm as well as the differential pressure between rooms all the time. |

| Classification | IEST Recommended Air Change Per Hour (ACH) For Cleanrooms | Ceiling Filter Coverage, % | HEPA or ULPA Filter | |

|---|---|---|---|---|

| ISO Class | FS-209 Class | |||

| 9 | NA | No recommendations | 5 - 15 | HEPA Filter |

| 8 | 100,000 | 5 – 48 (20 ACH by FDA) | 5 – 15 | |

| 7 | 10,000 | 60 - 90 | 15 – 20 | |

| 6 | 1,000 | 150 - 240 | 25 - 40 | |

| 5 | 100 | 240 - 480 | 35 - 70 | |

| 4 | 10 | 300 - 540 | 60 - 90 | ULPA Filter |

| 3 | 1 | 360 - 540 | 60 - 100 | |

| 2 | NA | 360 - 600 | 80 - 100 | |

| 1 | NA | 360 - 600 | 80 - 100 | |

Specialized Laboratories (Electromechanical)

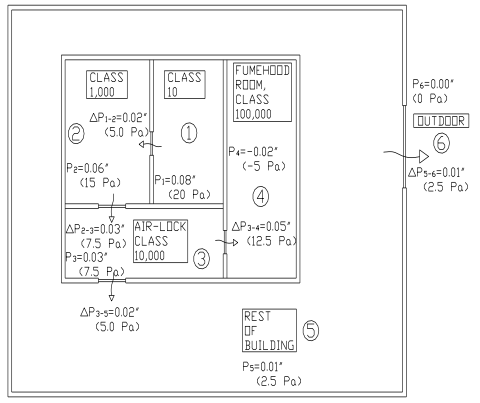

MegaTec can fulfill the client's requirements such as required differential pressure between the adjacent spaces, cleanliness class, etc by proper design, installation, start-up and commissioning. Bio-safety level labs, Chemical labs, research labs, and animals Labs are some examples of the specialized labs.

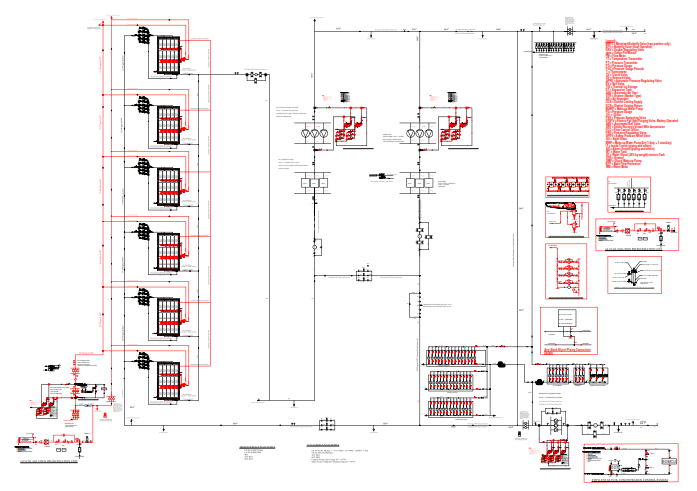

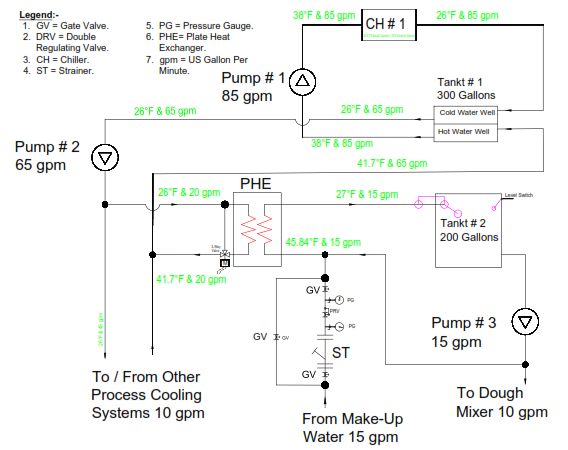

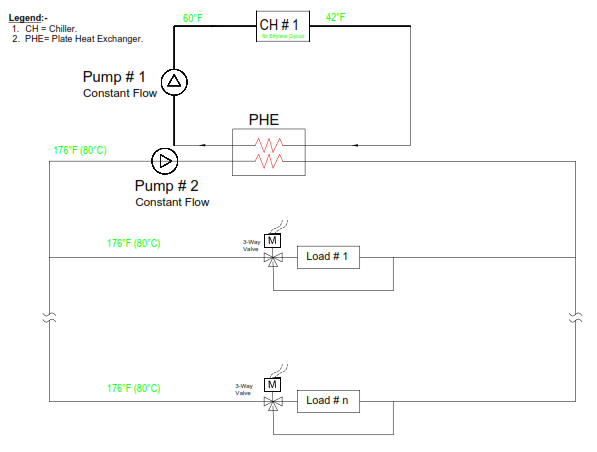

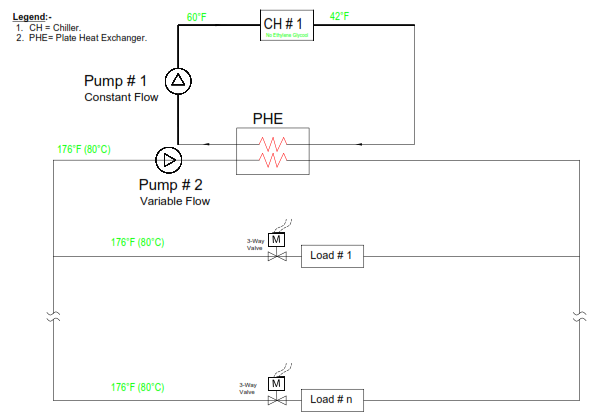

Industrial Process Cooling Systems

MegaTec shall provide the industrial process cooling below the freezing water temperature, above the freezing water temperature and even above the standard chiller chilled water supply temperature, by properly design the process cooling system as per the process(s) requirements.

Industrial HVAC Systems

- HVAC system for any high sensible heat application to give the most economical solution, for any factory or industrial facility (due to electric motors, electric heaters, etc).

- HVAC system for any high latent heat application to give the most economical solution, for any factory or industrial facility (due to electric motors, electric heaters, etc).

- Any HVAC industrial system which require special condition for proper manufacturing.

- Any other industrial HVAC system even it is so complicated.

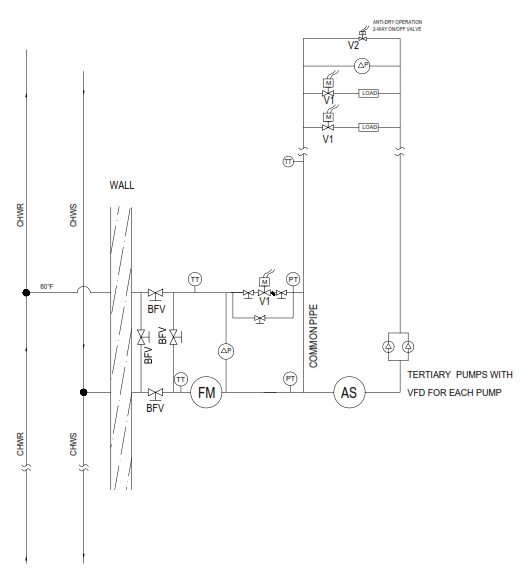

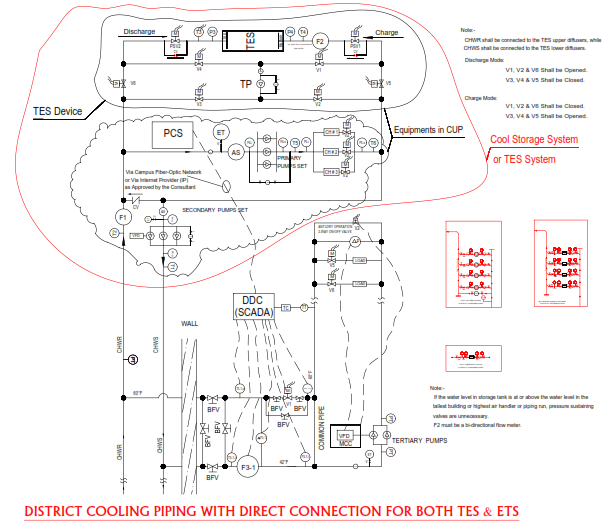

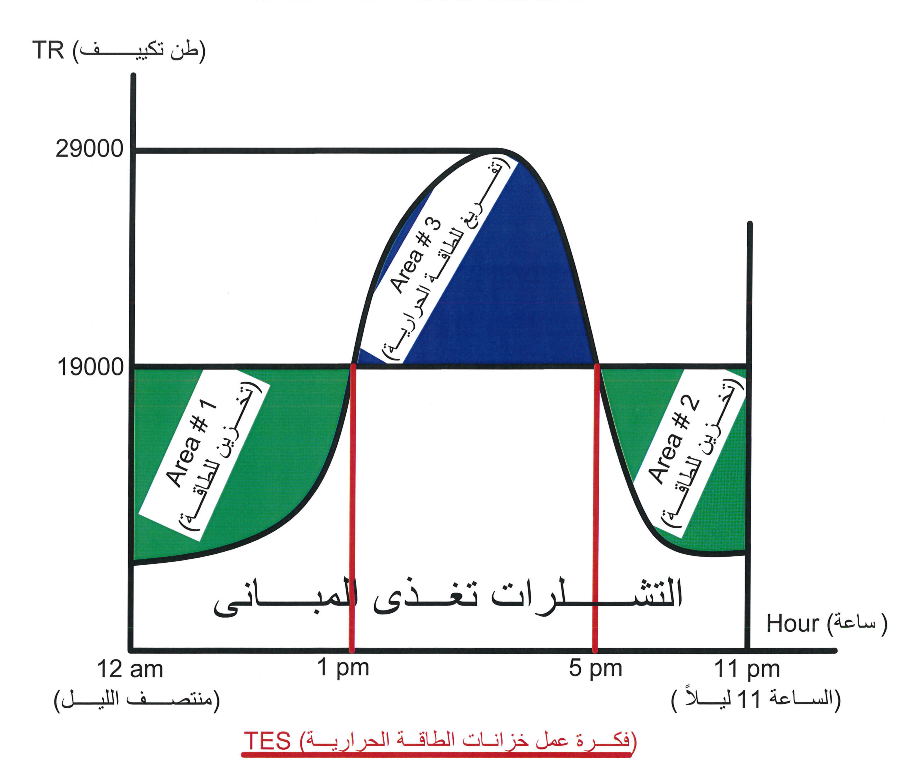

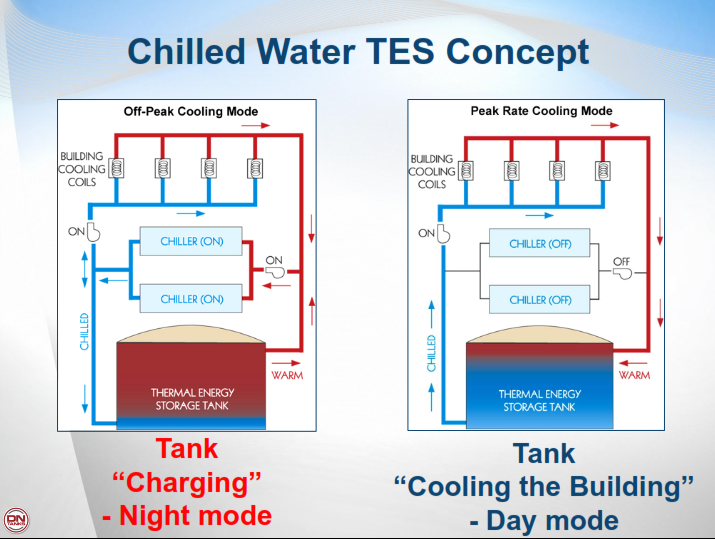

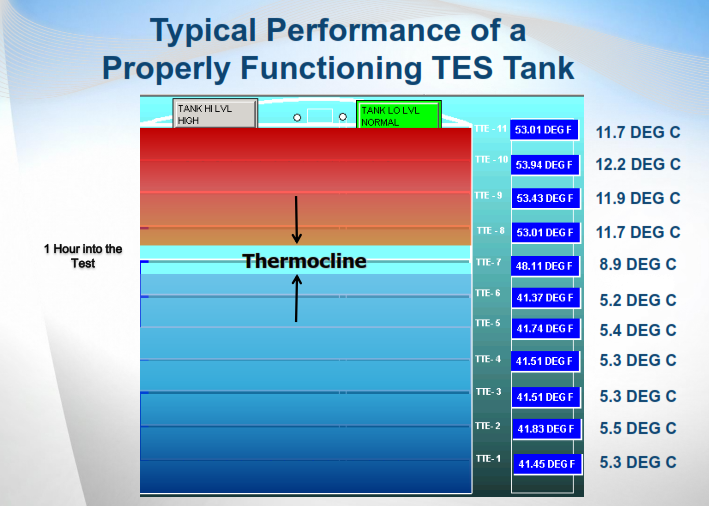

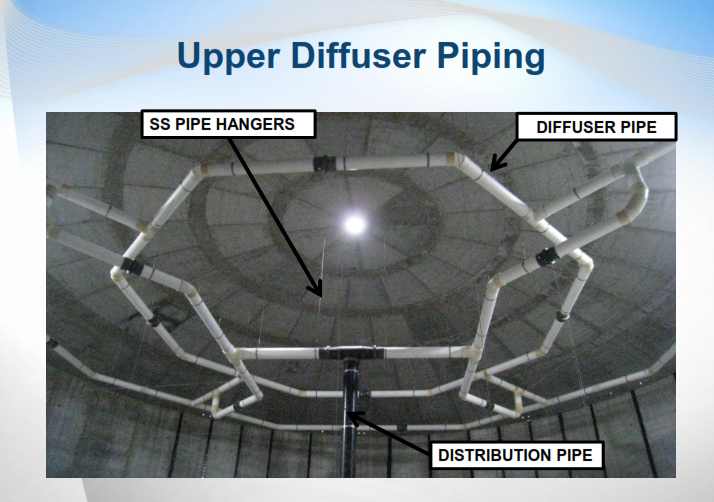

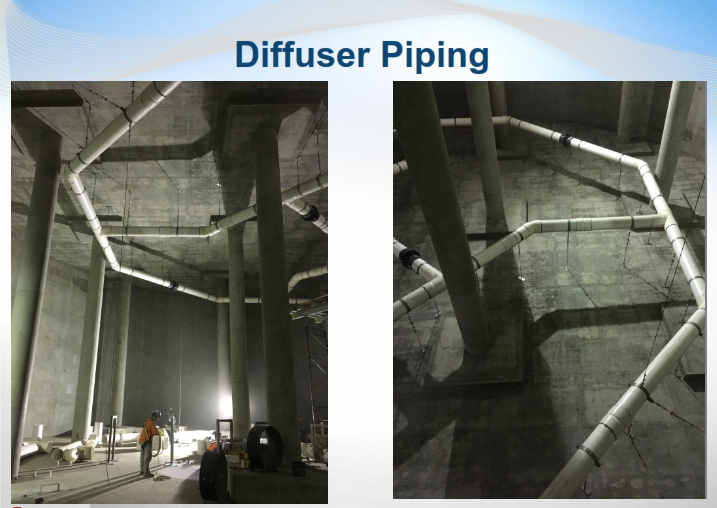

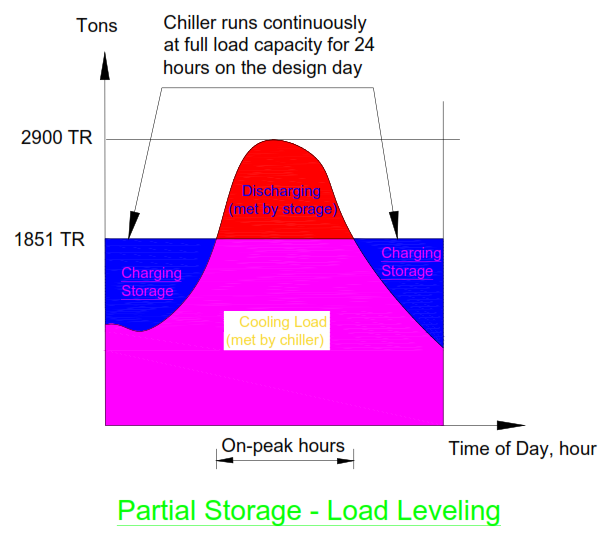

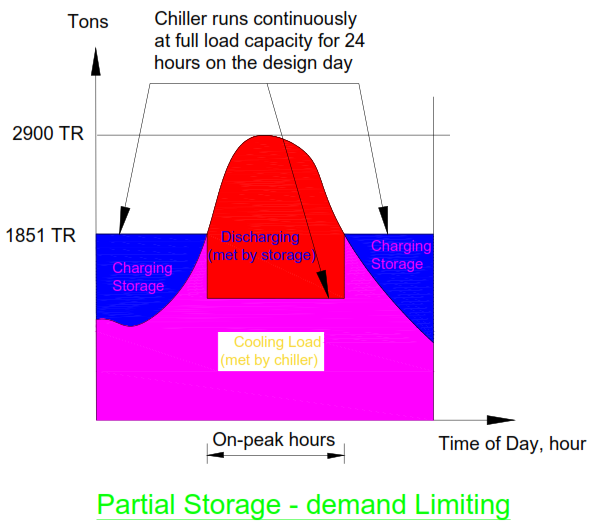

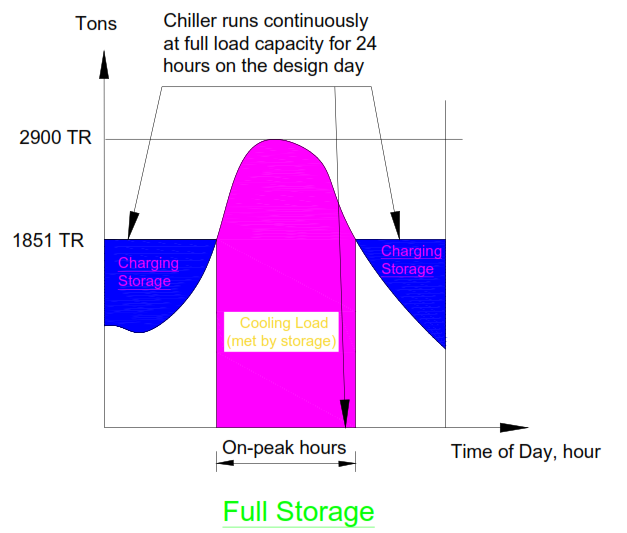

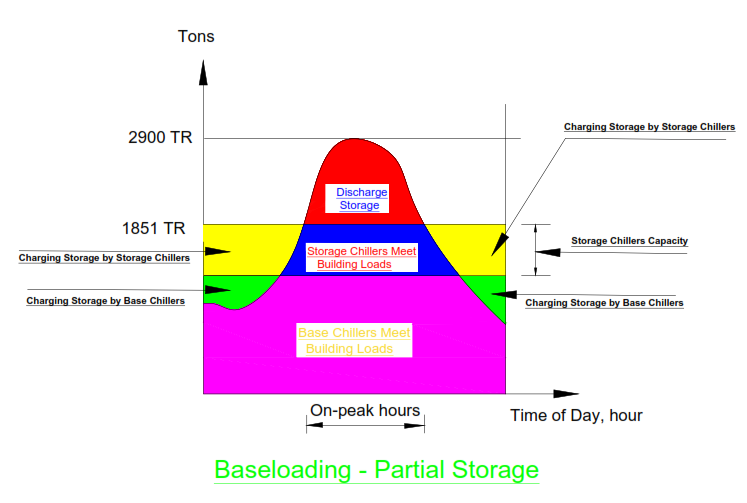

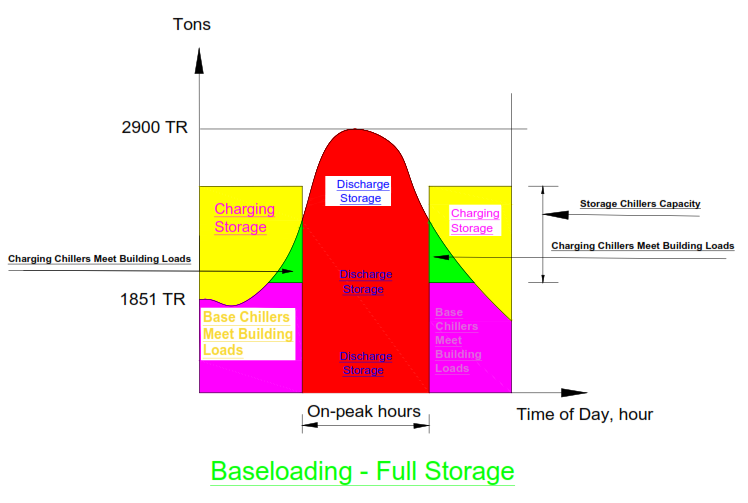

TES Systems

MegaTec can conserve energy by about 10% : 15% of the required power to any chilled water system, for the benefit of our clients, by using the most economical customized thermal energy storage (TES) system.

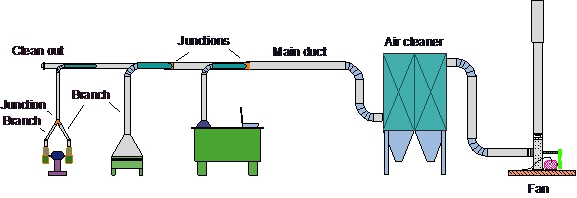

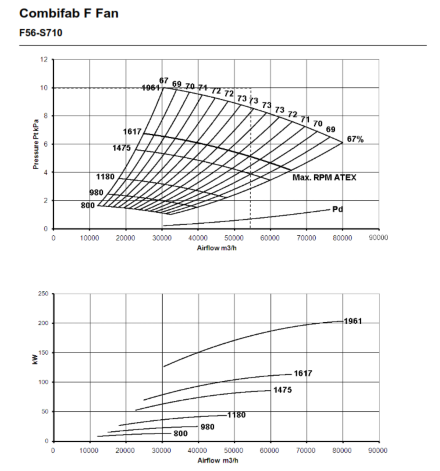

Industrial Exhaust Systems

Industrial processes and/or equipments require special design requirements. These special requirements require qualified specialist and MegaTec team can fulfil efficiently these requirements.

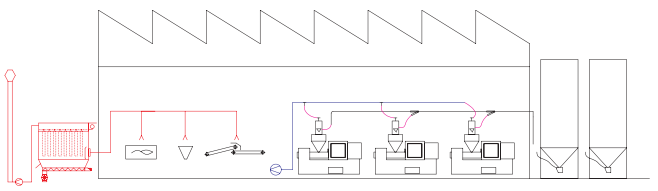

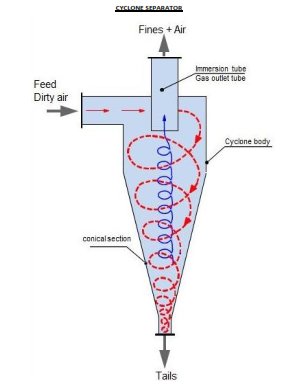

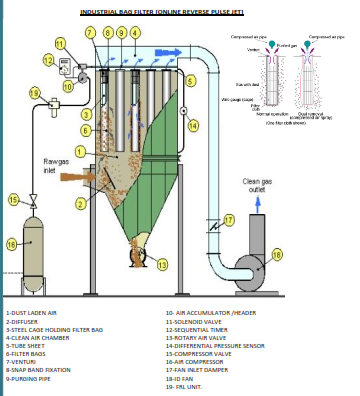

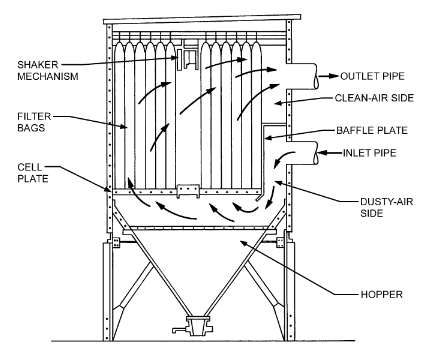

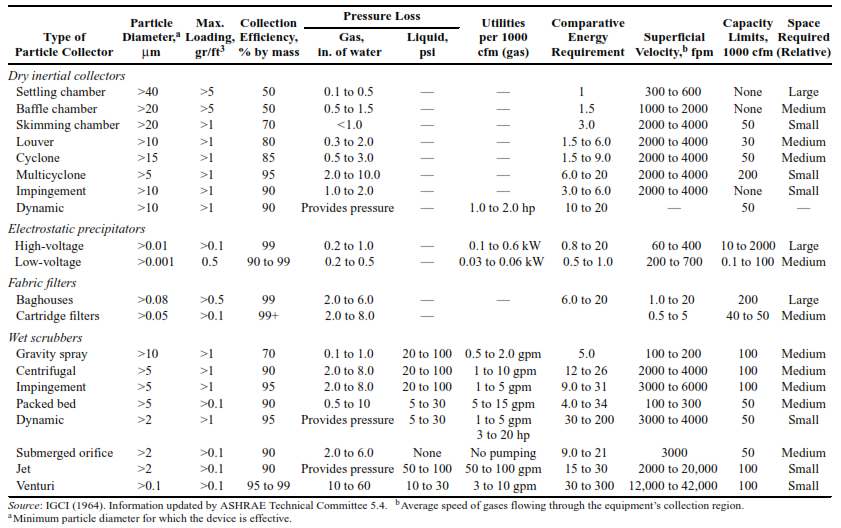

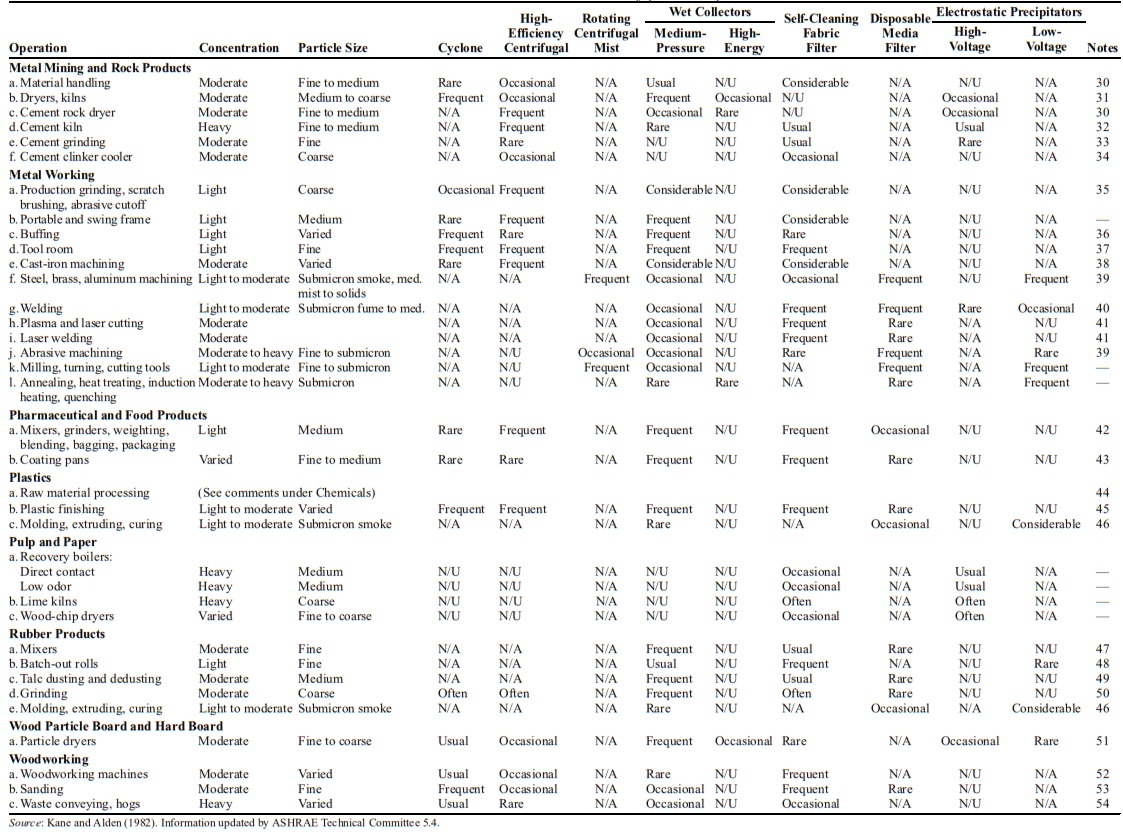

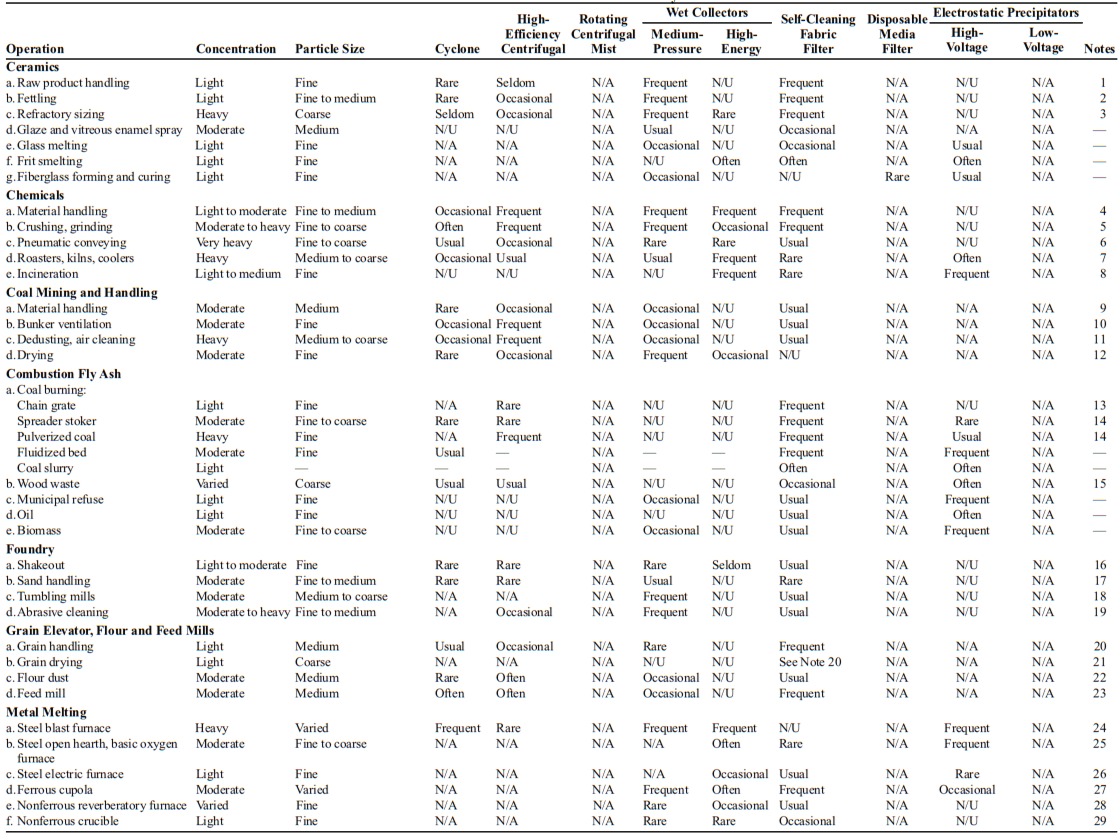

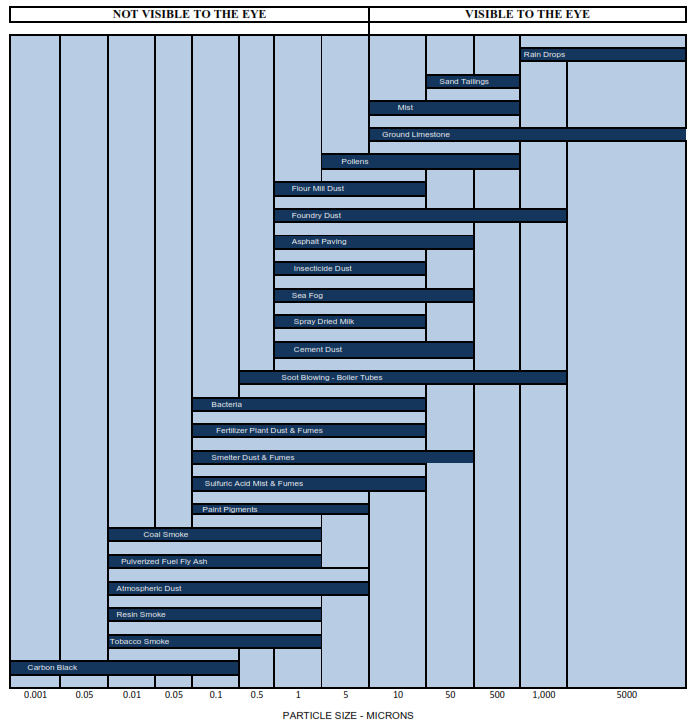

Particulate Contamination Control Systems

If any client is suffering from particulate contamination (such as cement aerosol, PVC powder, cotton aerosol, etc), MegaTec can provide cost effective total solution to effectively eliminate the potential risk, based on our client's financial capability.

NoteThe gaseous and/or particulate contaminants can be founded in many industrial applications such as cement factories, foundries, lime Kilns, chemicals industries, plastic industries, asphalt production, bulk material marine transportation, pharma industries, and many other applications.

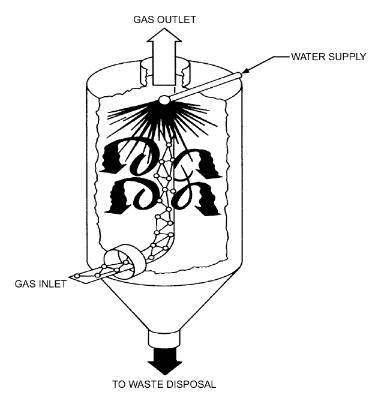

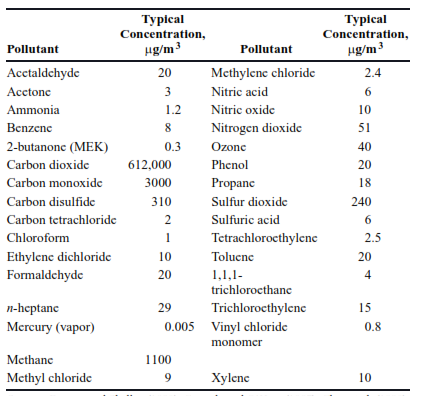

Gaseous Contamination Control Systems

In case one of our clients encounters negative results from any gaseous contamination, MegaTec can efficiently eliminate the potential risk, based on our client's financial capability.

NoteThe gaseous and/or particulate contaminants can be founded in many industrial applications such as cement factories, foundries, lime Kilns, chemicals industries, plastic industries, asphalt production, bulk material marine transportation, pharma industries, and many other applications.

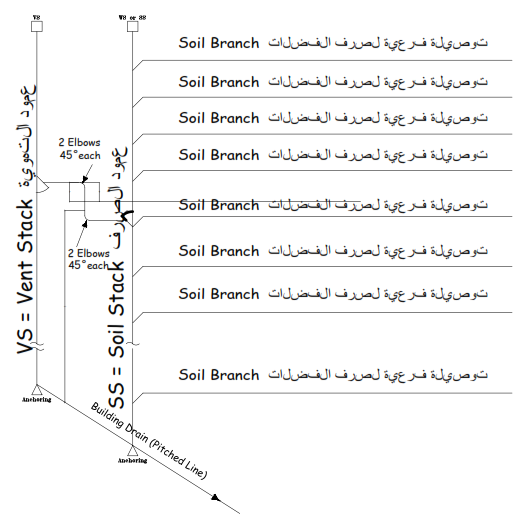

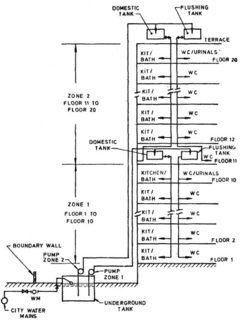

High Rise Buildings Electromechanical Systems

High rise buildings (300 ≥ tall building > 100 m, 600 ≥ Supertall Building > 300 m and Megatall building > 600 m in height as per ASHRAE) has a unique and formidable challenges to design, install, start-up and commissioning.

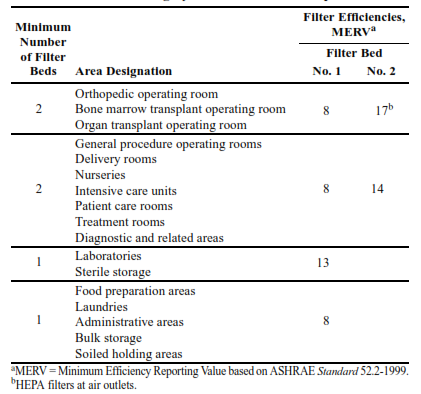

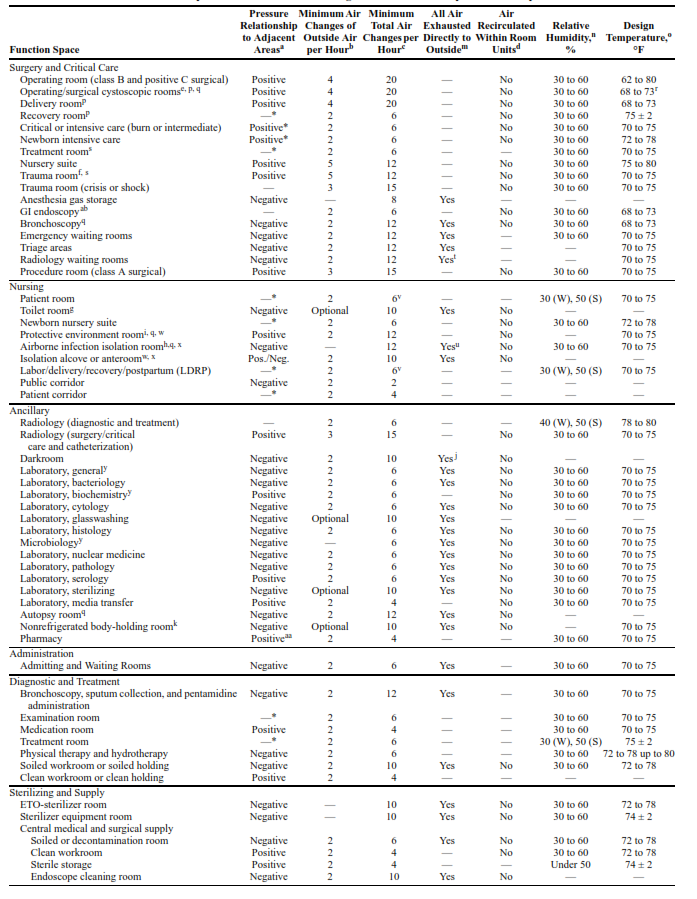

Healthcare Electromechanical Systems

Healthcare electromechanical systems (HVAC, plumbing, FF, etc) require a special expertise. For example HVAC system in any healthcare facility requires differential pressure between some spaces in order to eliminate infection. This challenge can be done efficiently by MegaTec team.

HVAC Chronic Problems Total Solutions

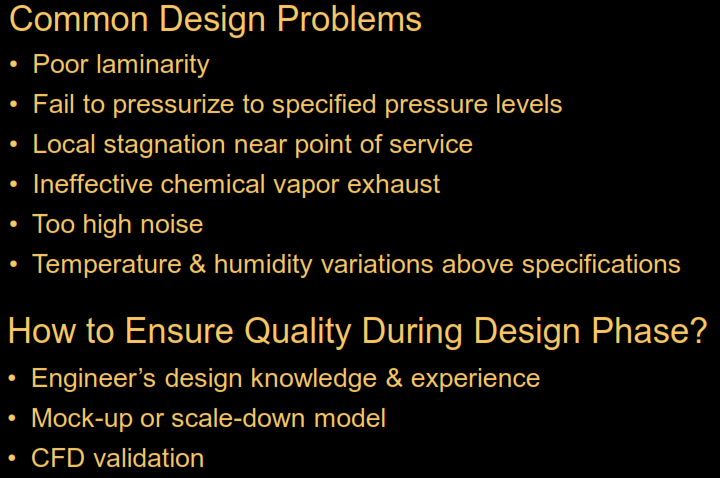

Many HVAC systems are suffering in the market now from many chronic problems due to improper design and / or selection. The clients of these systems are also suffering and paying more money and cannot find the qualified team to permanently resolve these chronic problems. In this case MegaTec shall resolve your HVAC system chronic problem with warranty, using the most economical solution, advanced instrumentation, latest software program(s) if needed and very qualified engineers.

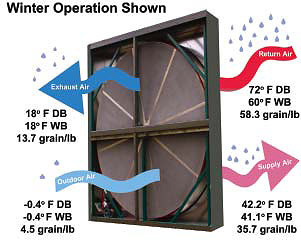

HVAC Heat Recovery Equipments and / or Systems

MegaTec can recover the wasted energy to maximize the HVAC system efficiency and reduce the operating system cost.

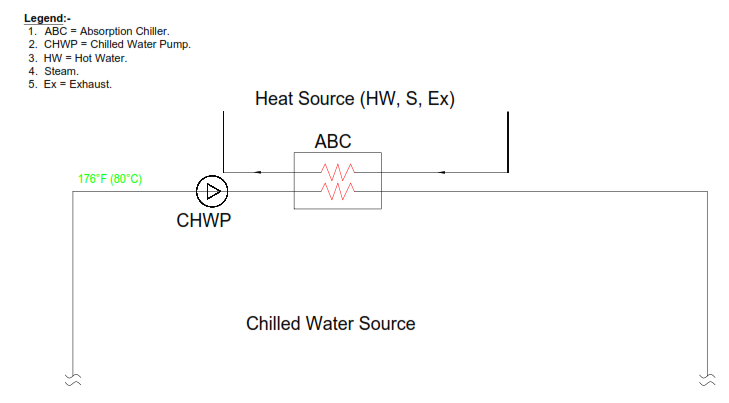

District Cooling and Heating Systems

One of the most advanced HVAC systems is the district cooling and heating system. This system is used now in USA and European countries and represents 50% of the total HVAC systems capacities. This system (with the help of TES) is imposed by Emirate of Dubai due to the tremendous benefits of this advanced system.